Introduction

Yixing clay teapot come in different forms, and you must be wondering why the same clay produces a different appearance. This article will answer your questions and take you through a comprehensive understanding of the firing process of Yixing Zisha teapots. I will introduce you to the working principles of electric kiln, dragon kiln and wood kiln, as well as the oxidation reduction and wuhui processes. Let’s get started.

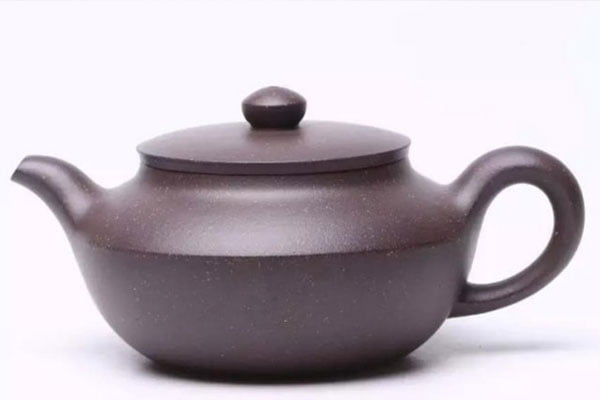

Firing is the last and most critical stage in the production of Yixing clay teapot. After the purple sand is transformed into a pot billet from clay, it is left for two or three days to dry and remove the moisture before being placed in the kiln.

The firing process, a procedure referred to as firing, entails high-temperature calcination that chemically transforms the clay billet into a hard, smooth, and unbreakable Zisha teapot, and it also involves a series of physical and chemical changes that solidify the shape of Zisha and enhance its properties.The color and denseness of the fired work vary depending on the temperature and environment of the firing. Therefore, pots made from the same clay at different temperatures will exhibit color differences.

The firing process of purple clay teapot has continuously improved throughout centuries of pot-making history. Before the 1950s, the firing of Yixing Zisha teapot was conducted in a dragon kiln. This practice gradually shifted to a reverse-flame kiln, and today it is typically done in a push-plate kiln, a gas kiln, or an electric kiln.

Let’s discuss the differences between each of them.

Electric Kiln

Among the Zisha firing processes, the electric kiln is a relatively stable one. But why?

- The interior space of an electric kiln is sealed, leading to high heating intensity and thermal efficiency. As no open flame is produced, there is no ash or smoke that could impact the firing of the purple sand pot.

- Electric kilns offer relatively stable sintering of Zisha pots because of their precise control over temperature changes.

However, the general electric kiln, whether it is firing a cup or a teapot, can accommodate only a limited number of objects. This limitation reduces the output, which may slightly increase the price.

Sintering of yixing clay teapot refers to the physical state in which Zisha melts under a certain high temperature state with low melting point substances. These substances fill the voids between unmelted substances without reaching the degree of carbonization (scorching black) or calcification (appearance of pinholes and bubbles).

The temperature range between the beginning of melting of the low-melting material and the critical point of the emergence of bubbles, pinholes, and coking is referred to as the sintering temperature range.

Push Plate Tunnel Kiln

The working principle of push plate kiln is to place the purple clay teapot on the temperature resistant plate of the sagger(a protective fireclay box enclosing ceramic ware while it is being fired.) and push it into the kiln by hydraulic press. It has the appearance of a long tunnel, usually 50 to 60 meters long.

They are divided into a preheat zone (at the entrance), a firing zone, and a cooling zone (at the exit). The firing zone is situated in the middle of the kiln body, and the preheating zone uses radiation heat transfer from the firing zone to gradually preheat and warm the blanks loaded onto the pusher plate.

During the cooling process, the plate is pushed outwards, and the products on the plate gradually cool naturally in contact with the outside temperature. The temperature of the products as they exit the kiln is generally around 200℃.

There are two types of kiln firing: open-flame and closed-flame. Open-flame firing is generally used nowadays, as it has the advantages of low heat consumption, easy construction and maintenance, and simple control of the firing atmosphere compared to the compartmentalized pusher kiln.

The open-flame pusher kiln boasts a uniform and pure flame during firing, resulting in a relatively pure color in the fired ware.

Dragon Kiln

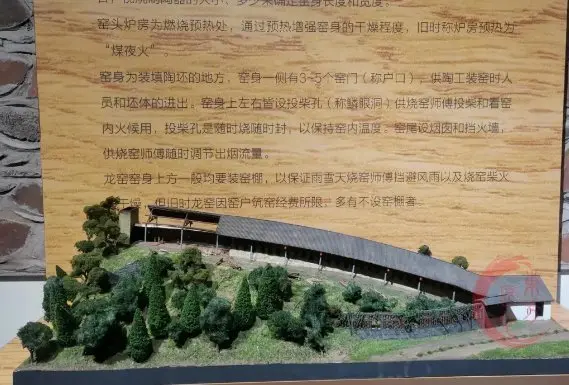

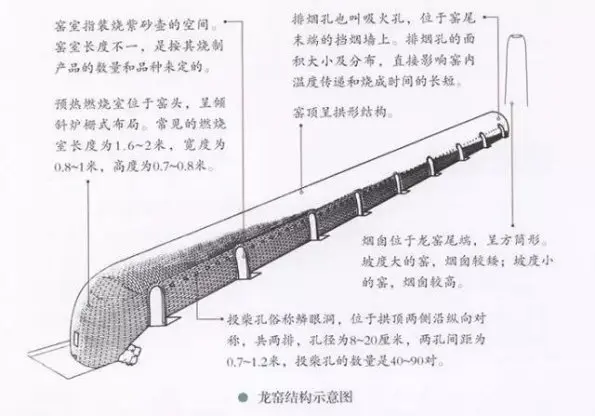

In ancient times, Zisha teapots were fired using the dragon kiln. Shaped like a dragon, the dragon kiln is a long, curved tunnel built with bricks on the slope of a mountain.

Archaeological excavations show that there were several dragon kilns in Yixing, including the Tang Dynasty’s Yixing Jianshen dragon Kiln, the Song Dynasty’s Yixing Yangjiao Mountain dragon Kiln, and the Ming and Qing Dynasties’ Yixing Ou Kiln. The oldest of these, the Jianshen dragon Kiln, is located in Jianshen Village, Shishu Town, and its existing kiln site is a provincial cultural relic.

Another dragon kiln from the Ming Dynasty, which can be called “antique,” is located in Qianshu Village. It still has strong fire today and continuously fires batches of purple sand ware.

Dragon kilns are generally 30 to 70 meters in length, about 12 meters high at the top, and have an inclination angle of 8° to 20°. Their structure is divided into kiln room, kiln roof, firewood holes, kiln bottom, preheating combustion chamber, smoke exhaust holes, chimney, and kiln door.

The dragon kiln is characterized by its simple structure, convenient material, low cost, and quicker production. There is no fixed firing zone, and the firing point gradually moves with time and temperature along the kiln from top to bottom. The heat utilization rate is also higher. The disadvantage is that the production cycle is long and the fuel is pine wood, which consumes wood.

In the early days of the founding of People’s Republic of China, there were nearly 100 dragon kilns in the Yixing area. They produced Yixing Zisha teapots using daily flames and smoke, and consumed over 250,000 tons of firewood annually.

Nowadays, the domestically utilized dragon kiln, which fires pottery only infrequently and may only be opened once or twice a year with government approval, yields a finished product success rate of about 60%, making the finished pots crafted in these kilns precious. However, given the prevalence of fake dragon kiln pots in the market, a high degree of caution is necessary when collecting and purchasing them.

These pictures were taken at the Dragon Kiln

Chai Fired Kiln

The making of Yixing clay teapot involves a very special technique called Chai-fired(Firewood Kiln). This process is the opposite of Dragon Kiln(Chai-fired requires ash, and the dragon kiln has no ash).

There are many fire marks on the surface of the finished chai fired purple clay pot. Because of the uncertainty of the trace, this is also the most attractive part of Chai-fired.

Chai-fired Zisha is not as simple as using natural firewood to burn out, despite the literal meaning of the word. The firing of a wood-fired teapot often takes more than two or three days, and several tons of wood are used at a time, depending on the size of the kiln and the number of burns.

On the first day of firing, the kiln is lit with low-temperature smoke. Only after the carbon released from the firewood fills the pores of the clay billet and the surface of the billet shows the black color of carbon can the process continue to heat up. This takes about 30 hours.

The temperature is raised gradually to 300°C, and the clay is slowly fired to allow the billet to dry. As time goes on, the temperature becomes more difficult to raise. From 300℃ to 800℃ it often takes 6 to 7 hours, and from 800℃ to 1000℃ it takes 10 hours. Sometimes the temperature may not necessarily rise by 1-2℃ after 1 to 2 hours of firing.

Redox is an essential part of Chai-fired . When the time is right, the kiln vent is blocked, which is an extremely critical step in redox.

The same clay fired in a different location will produce different results.

The color and texture of a Chai-fired Zisha teapot do not depend on the potter’s skill, but only on the fire and ash. Human will can guide the direction of the final product to some extent, but it does not play a decisive role.

Teapots made by the Chai firing process are very expensive because of the high rate of destruction due to the unstable environment in the kiln. Including the labor and wood used, the cost of a yixing clay teapot is extremely high.

Due to the laborious, time-consuming, and labor-intensive process, the heirs of wood-fired Zisha teapots are very rare.

In Yixing, the price of firing a wood-fired purple sand teapot far exceeds that of ordinary gas, electric, and coal kilns. The better the craftsmanship, the higher the charge. After all, compared to these firing methods, the ancient wood-fired pots are much less stable. But that is why Chai-fired will have more unique elements that make each Chai-fired appliance unique:

1.Different Air Holes

Chai-fired in the firing process constantly adds firewood, so the temperature is sometimes high and sometimes low, forming bubbles of different sizes with a certain sense of hierarchy.

2.Different Glaze Textures

The firewood, generally pine, bamboo, and all kinds of wood, produces burning ash and flames that flee into the kiln, which will produce a natural fall of ash on the blank. After a long period of high temperature fusion, the ash forms a natural gray glaze with a warm color, rich layers, rough and strong texture.

3.Different Tea Soup Changes

After the wood-fired redox method of firing the purple sand tea set, there is a certain effect of changing the water quality. With its tea, it can play the role of soft water, which is desirable for brewing.

Reduction Firing

The firing of ceramics varies depending on the type of object needed and the number of firings required. There are two types of firing methods: oxidation firing (O.F.) and reduction firing (R.F.).

During firing, the entire kiln becomes a space, and in addition to the objects that need to be fired, other empty spaces will be filled with gas.

When a kiln is fired, if there is enough oxygen entering the kiln room to make it fully burn, it is called “oxidation firing.” Oxidation firing means that there is always sufficient oxygen burning in the kiln chamber during the firing process, like electric firing that belongs to this type of firing (hence no flame in electric kilns).

If the kiln is made to lack oxygen through a skillful technique, the fire extracts oxygen from the soil and glaze, resulting in a reduction firing. during reduction firing, the kiln temperature rises to around 900 ℃ and then the oxygen in the kiln is reduced. This creates a lack of oxygen in the kiln, causing the flame to burn oxygen from the bad body or boron, and resulting in the oxidized metal in the billet changing in nature and color. This is why the effect of color during reduction firing is different.

This difference in atmosphere means that the same teapot will have different colors when fired in an electric kiln, gas kiln, or chai-fired kiln. Additionally, the effect of firing at different temperatures is also completely different.

Using reduction firing, different mud will show different effects:

Wuhui 捂灰(Black Clay/ Heini)

Wu Hui is a unique craft used as a purple clay teapot decoration technique. The method of making Wu Hui involves two firings.

The first firing is done at a low temperature, and the second time, before entering the kiln, some special wood charcoal, rice husk, or various special plants such as pine branches are sprinkled on the kiln bottom. The already fired purple clay pot is then buried in the rice husk in the box bowl and sealed. It is then placed in the kiln and fired again. The temperature rises slowly during the firing process, and the rice husk is ignited but cannot burn fully due to a lack of sufficient oxygen. The carbon molecules in the rice husk are absorbed into the teapot body, forming black color, and this process is called “Wu Hui”.

Well-made Wu Hui is black, like high-quality ink, with a warm feeling and the characteristic of “kiln change by human”.

Wu Hui teapots will not fade. The iron element reacts with wood charcoal powder, and the oxidized iron is reduced to ferrous oxide, which is black. Therefore, the teapot after Wu Hui appears black.

The Wu Hui teapot is full of “dust” when it comes out of the kiln, so it needs to be cleaned inside and outside before use. Then soak it with tea water for two days to fully neutralize the acidic substances in the charcoal ash and tea alkali, so as to discharge turbid substances. Clean the spout, handle, lid, etc., and thoroughly clean the remaining charcoal ash so that it will not appear muddy water when used.

Initially, the process of wuhui was used to cover flaws. However, many people now choose to wuhui their intact Yixing clay teapots. This is because it enhances the teapot’s beauty with use over time.

More about the Firing Temperature

Finally, a little knowledge about the firing temperature of Yixing purple clay teapot is added.

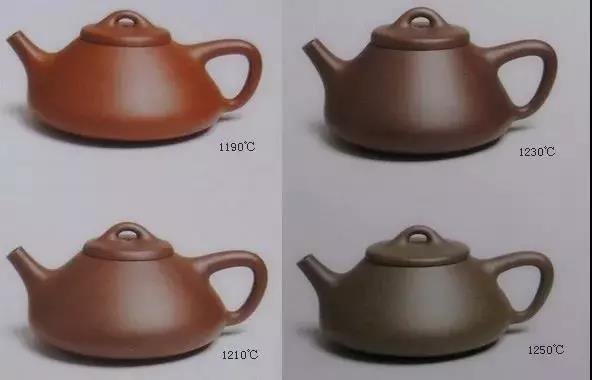

Is the higher firing temperature of Yixing clay the better? Different clay materials of Yixing purple clay have different sintering temperature ranges. Within this temperature range, the teapot body will present different effects at different temperatures of the same clay material, but it needs to be moderate, not the higher the better.

For example, people who like duan clay often ask about the problem of black spitting. The spitting black is caused by the insufficient temperature of the clay when it is fired in the kiln.

On the contrary, too high temperature is called over-firing. The teapot body will appear very rough, accompanied by small cracks, even deformation, blistering, etc.

Zhuni clay has higher crystallinity, and Duan clay is relatively good, which is also one of the reasons why Duan clay has good air permeability.

In actual operation, the first firing is always under-fired, and the second firing will meet the required temperature. This is also what we often say about firing Yixing purple clay teapots twice, firing at low and high temperatures.

- The first firing is at a low temperature. After firing, take it out and repair the mouth and lid wall to make the teapot mouth and lid more flat and tight.

- The second firing is at a high temperature, reaching the crystallization temperature of the clay material. At this time, the teapot is generally finished.

Some Yixing clay teapots may find that the sand color is not ideal after the second firing, so they will be fired again in the kiln for the third time. The more times it is fired, the higher the risk of damage. In addition, the first firing of Yixing purple clay teapot cannot be watered, otherwise there will definitely be problems in the second firing.

Due to the slight differences in mineral elements contained in Yixing purple clay, there are many color differences presented at different firing temperatures. Here are some effect pictures:

The same clay material has different color effects under different firing atmospheres. For example, purple clay presents purple-red, purple-brown, deep purple and other colors in an oxidizing atmosphere, and presents a variety of green-black tones in a reducing atmosphere.

Because in an oxidizing atmosphere, the iron in Yixing purple clay forms red-brown iron oxide, while in a reducing atmosphere it forms green-black ferrous oxide.

Firing at high temperatures and multiple times are ultimately a firing technique that serves the utensils.Regardless of the firing temperature and number of times, as long as it can present us with a utensil that is as close to perfect as possible, it is a good technique worth pursuing.

Conclusion

I hope this article has given you a detailed understanding of the various firing processes of Yixing clay teapot. Each technique has its unique charm and influence, shaping the pot’s final appearance, texture, and color. As complex as the process may be, it’s the meticulous attention to these details that bring each Zisha teapot to life.